As electronic components get ever smaller, they enable the development of increasingly compact products. We are continually being asked to fit them into tighter and tighter enclosures and at ever reducing development times. Therefore, by the time a first PCB has been assembled we have to be sure not only that it works but that it fits into the space available. Tight deadlines demand a right first time approach.

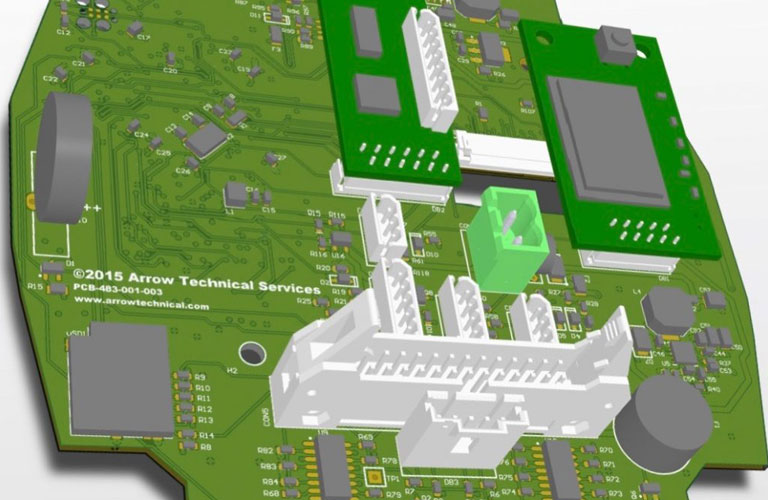

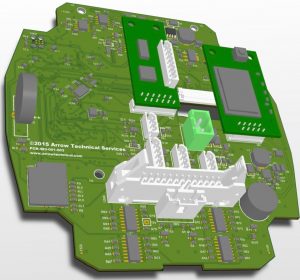

To assist with this all our electronic designs are developed in 3D-CAD and well before a first one is made, we can output a 3D step file of the fully assembled PCB, such as the one above, which is compatible with most 3D solid modelling CAD packages. This allows the mechanical design engineer to fit our virtual PCB assembly inside their virtual enclosure and check for size and fit before either PCB or enclosure are made. Following this, we can use 3D rapid manufacturing techniques to manufacture both an enclosure and a PCB of exactly the size and shape to ensure that they physically fit and are easy to assemble, disassemble and service.

With these assurances, we can commit to manufacture of the PCB and be sure the board will fit inside the space available. Of course, we have also used circuit simulation techniques to ensure the circuit works once it is built.

By employing these advanced design techniques, we are able to develop new products at minimum time with maximum confidence that the finished article will meet its design criteria first time around.

For more information on how we can develop your next PCB to the same exacting standards then please contact us at:-