We are already well known for developing advanced electronic products for numerous blue-chip clients. Most people are aware that we design products from an early idea to a fully working prototype. However, fewer people are aware that our technical services extend way beyond the creation of a prototype and that we follow the project through to volume PCB Assembly (PCBA).

Most modern products which are sold in the UK, EU and further afield such as the Middle East, Australasia and Northern America must be tested to various national standards which apply in each geographical region around the world, and this can be extremely expensive to the uninitiated.

Arrow Technical have been advising clients how to meet the different technical standards, such as UKCA, CE, UL and ISO for many years and we work closely with several test houses who provide qualified test reports, traceable to national standards, to prove the product under test does indeed meet the appropriate standards required for sales into a specific market. We also prepare Technical Construction Files as some product types require – especially electronic ones.

Testing to national standards is a time consuming and expensive process and it is only valid when done on a production ready sample as will be sold. It is not unusual, for some people to consider their electronic product’s compatibility only right at the end of the design process when the cost of making any late alterations to the electronic design or PCB layout adds precious time and additional cost to the overall process of making the product meet the required standard.

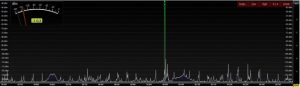

Using our in-house test facility, we can design and test the performance of the product for EMC compatibility, electrical safety and general UL compatibility from the start and if we spot anything unusual then we have plenty of time to identify the problem and fix it. When we are happy that the product meets our in-house pre-compliance tests then we are reasonably certain that we will get a satisfactory result when the final product is submitted to a (expensive) certified test house.

RF Emissions Spectrum

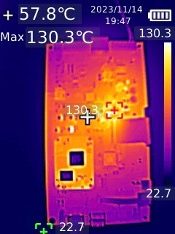

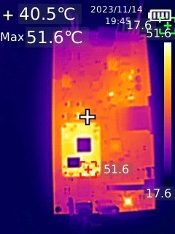

Depending on the product type, we also do reliability testing such the example shown below. Functionaly and visually, the prototype worked perfectly but when viewed by our thermal imaging system then an undesireable hot-spot became apparent. After about half an hour of testing we measured temperatures up to 130C which would degrade the component over time and it would eventually fail. After the redesign we only recorded temperatures around 50C which would extend the product life significantly.

Visual Image

Thermal Image with 130C Hot-Spot

No Hotspot